In-lab Activities:

This week in lab we briefly discussed the project presentation outline, and how we were going to present the device. We talked about the possibility of showing a demonstration piece of our device as part of our presentation. In lab, we went ahead and started discussing ways to better program our device. As a final deliverable, it was essential for the device to be as user-friendly as possible. The group also discussed how to improve the final report as a whole. As a group, we also modified the the code so that it was as user friendly as possible.

Below is a picture of our modified code:

|

| Final Arduino code for the solenoid |

Outside of lab this week, our group finalized everything about the device. The entire device was completed along with the final report and presentation. A final update of the Arduino code was also modified and ready to present.

Below is a picture of the finished deliverable:

|

| Group's Automatic Plant Feeder |

If you would like the user manual for this device, email David at db845@drexel.edu or Jose at jaa93@drexel.edu...

Week 8

In-lab Activities:

This week in lab, we came up with a small test that should take place in order to determine where the solenoid in particular should be placed. The test would consist of different positions for the solenoid to show which way would provide accurate results for our determined flow rate. The position of the solenoid can be a factor of both gravity and hydrostatic pressure. This test would lead up to a more advance test that would be used towards the code of our Arduino.

The solenoid valve was eventually positioned in this direction to provide flexibility for the tubing and the electrical component of the device.

Outside-lab Activities:

The flow rate experiment for the device came through this week's outside activities. The first experiment was done at 36 inches of height. The data gatherer was to open the valve until it released 1000mL of water. This repetition was done for 11 more times until the tank was completely empty. The different levels of 1000mL created a flow rate vs. level graph. The trendline for the graph showed the formula that will be implemented in the Arduino code to power the Solenoid. Accurate testing, and many trials provides enough data to determine how to properly program the Arduino.

Below is a picture of the results obtained from the experiment:

Another flow rate experiment was done at a higher position in order to compare the results and determine which would benefit the user more.

The integration of subsystems also took part this week. The bottom portion of the tank was completed to resemble our intended design. A preliminary sketch of our integration is shown below:

As you can see, the electrical housing and the solenoid were placed neatly within the base of the device. This met our requirements and constraints for both the solenoid and the Arduino.

Week 7

In-lab Activities:

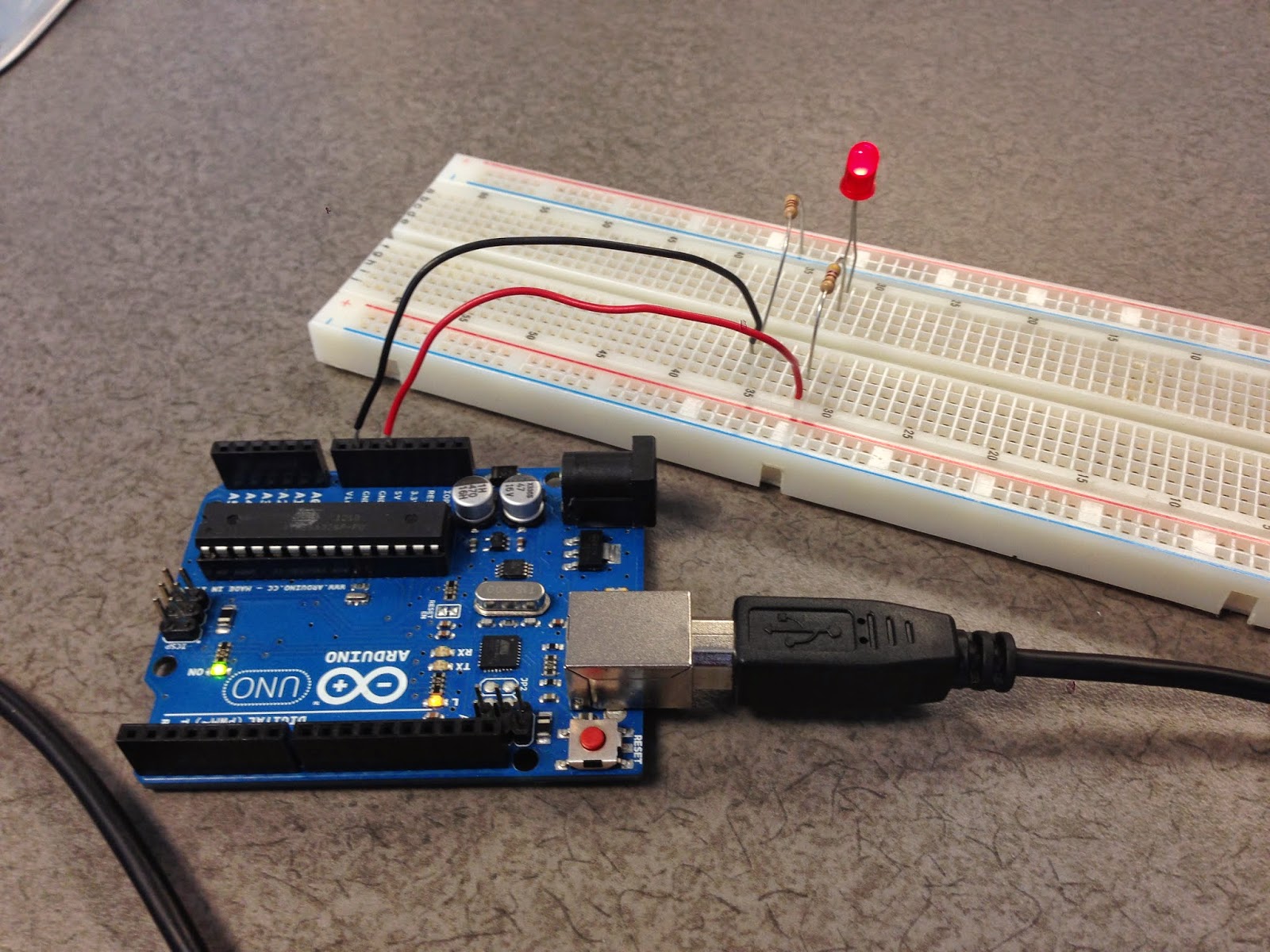

This week's main activity was putting together the actual electrical subsystem together: the solenoid, the breadboard with wires, and the Arduino board. The group began by acquiring the following electrical devices:A 12 VDC power supply the proper resistor, transistor and diode. As the lab progressed. the group began discussing ways to house the electrical setup. We reached an agreement that the electrical component must be housed underneath of the device in order to prevent water from reaching it.

Below is a picture of a preliminary electrical functional setup:

Outside-lab Activities:

In-lab Activities:

This week in lab our group discussed the wiring diagram for our electrical system. The wiring component of our device is an intricate part to our device's final deliverable. Our group discussed the possible ways the Arduino board and breadboard, along with the wires, could be wired to function properly. With the help our technical adviser and teaching fellow, our group was able to learn about the necessary electrical wires, diode, transistor, and resistor needed to power our device. The wiring diagram below exemplifies what our wiring compartment should look like:

Outside-lab Activities:

This week's outside of lab, our group obtained the brass fittings, tubing, and tank for the device. A preliminary flow rate experiment was conducted as well. This week we began doing measurements of the tank's spout and plastic tubing. We began developing ideas on how the tubing would be incorporated into the device itself. The plastic tubing must be long enough to reach the plant's roots yet short enough that it is able to keep the constant motion of water flowing downwards in the direction of gravity.

Below is a picture of our materials for the mechanical component of our device:

Week 5

In-lab Activities:

The main activity in lab for this week included the adaptation of a user-friendly component to the Arduino board and ultimately to the final product. The introduction of a seven-segment display, and buttons would provide the user with the capabilities of adjusting the device to his/her options. Also, an Arduino accessory called the Positive RGB LCB Shield Kit provides character display and basic functions for a user. We talked about ways on how the either of the two displays can be implemented into the Arduino and its program to facilitate the devices outputs.

Below are two pictures that shows the two kinds of displays our group is considering:

Outside-lab Activities:

Week 4

In-lab Activities:

The activities in lab for this week were based on the design of the two subsystems, the Arduino valve unit, and the plant watering frame. We came to the conclusion that developing a simple Arduino valve unit was best. The entire unit would be put together in a way that is both adherable to the base of the water tank, and easy to take apart in case of future programming. Our group also believed that the plant watering frame should be made from rubber hosing to provide the user with flexible adaptations.

Below is a picture of an Arduino board and a solder board placed together for appealing and flexible purposes:

Outside-lab

The group learned that putting together the valve with the arduino unit would require a bit of patience and adequate resources.

Week 3

In-lab Activities:

The activities in lab for this week included a brief with our technical advisers. We discussed power source for the Arduino. An additional deliverable was discussed: the wiring diagram of the Arduino component used in the device. Our group needs to do research on relays and transistors. A new concern is to find a way to safely power the device with an appropriate adapter and any relays necessary.

We made an adjustment to one of our constraints. We ordered our water tank. It is the Tablecraft 3-Gallon Beverage Dispenser. We also have to modify the nozzle of the water tank below. The final design needs to have a direct connection to the solenoid valve independent of the original spout.

Below is a picture of our water tank:

Outside-lab activities:

This week, our group focused on the development of the Arduino board component of the project. The first component that had to be address was the transistor. A transistor would act as an on/off switch for the voltage passing through.

Below is a picture of the initial transistor that we acquired:

The second component that had to be addressed for this week was the creation of the entire Arduino valve subsystem. The best way to put together this subsystem would be by using a solder board and soldering together the different parts.

The basic functions for the Arduino program were also learned. The main function that will be used for this project is the delay function that will allow us to properly run the water at a predetermined rate.

Week 8

In-lab Activities:

This week in lab, we came up with a small test that should take place in order to determine where the solenoid in particular should be placed. The test would consist of different positions for the solenoid to show which way would provide accurate results for our determined flow rate. The position of the solenoid can be a factor of both gravity and hydrostatic pressure. This test would lead up to a more advance test that would be used towards the code of our Arduino.

|

| Positioning of the solenoid valve |

Outside-lab Activities:

The flow rate experiment for the device came through this week's outside activities. The first experiment was done at 36 inches of height. The data gatherer was to open the valve until it released 1000mL of water. This repetition was done for 11 more times until the tank was completely empty. The different levels of 1000mL created a flow rate vs. level graph. The trendline for the graph showed the formula that will be implemented in the Arduino code to power the Solenoid. Accurate testing, and many trials provides enough data to determine how to properly program the Arduino.

Below is a picture of the results obtained from the experiment:

|

| Flow Rate depicting the results (36 inches of the ground) |

Here are the results for that experiment:

|

| Flow Rate depicting the results (69 inches of the ground) |

|

| Integration of subsystems |

As you can see, the electrical housing and the solenoid were placed neatly within the base of the device. This met our requirements and constraints for both the solenoid and the Arduino.

Week 7

In-lab Activities:

This week's main activity was putting together the actual electrical subsystem together: the solenoid, the breadboard with wires, and the Arduino board. The group began by acquiring the following electrical devices:A 12 VDC power supply the proper resistor, transistor and diode. As the lab progressed. the group began discussing ways to house the electrical setup. We reached an agreement that the electrical component must be housed underneath of the device in order to prevent water from reaching it.

Below is a picture of a preliminary electrical functional setup:

|

| Preliminary Electrical Setup |

This week's outside activities included the construction of our electrical subsystem of our device. The electrical subsystem features two major components: breadboard with the proper wiring, and the breadboard. Since the Solenoid can't be powered by just the Arduino board, a separate power source must be provided for it. The usage of a 12 VDC power sources gives the solenoid enough voltage to properly function. The electrical subsystem was put together in a housing unit as shown below:

The other subsystem, the mechanical portion of the device, was also constructed. It was important to take into consideration the positioning of the valve and the piping. The solenoid valve was to go inside underneath the water source, the actual tank. The reason for do this was so that it wouldn't be interfered with by outside sources. As for the plastic rubber hosing would provide the user to safely put together the device without actually having to alter the delivery system. The group decided that keeping everything in tact and together would provide the user with no impediments or structural problems.

Below is a picture of the completed structural device:

A blue tape was placed at the top of the device to signify where the user would have to fill the tank. It is essential that the user fill the tank to its entirety because the code was derived from the tank's constraints.

Week 6 |

| Housing unit for the electrical subsystem |

The other subsystem, the mechanical portion of the device, was also constructed. It was important to take into consideration the positioning of the valve and the piping. The solenoid valve was to go inside underneath the water source, the actual tank. The reason for do this was so that it wouldn't be interfered with by outside sources. As for the plastic rubber hosing would provide the user to safely put together the device without actually having to alter the delivery system. The group decided that keeping everything in tact and together would provide the user with no impediments or structural problems.

Below is a picture of the completed structural device:

|

| Mechanical component of the device |

In-lab Activities:

This week in lab our group discussed the wiring diagram for our electrical system. The wiring component of our device is an intricate part to our device's final deliverable. Our group discussed the possible ways the Arduino board and breadboard, along with the wires, could be wired to function properly. With the help our technical adviser and teaching fellow, our group was able to learn about the necessary electrical wires, diode, transistor, and resistor needed to power our device. The wiring diagram below exemplifies what our wiring compartment should look like:

|

| Wiring Diagram |

Outside-lab Activities:

This week's outside of lab, our group obtained the brass fittings, tubing, and tank for the device. A preliminary flow rate experiment was conducted as well. This week we began doing measurements of the tank's spout and plastic tubing. We began developing ideas on how the tubing would be incorporated into the device itself. The plastic tubing must be long enough to reach the plant's roots yet short enough that it is able to keep the constant motion of water flowing downwards in the direction of gravity.

Below is a picture of our materials for the mechanical component of our device:

|

| Brass fittings fitted into the spout. The dimensions of the plastic tubing can be seen as well. |

The preliminary flow rate experiment took place in order to enhance our perception on what type of data we are to likely to expect. Christian proceeded to open the valve on the tank until the level of the water in the measuring device equaled 500 mL and timed the results. He did 3 trials of this until no water could dispense. He then took the average of the three trials and used that value to find the rate of water dispensed (Rate=ΔVolume/Time; Units: mL/s). He then plotted the data in excel and found the line of best fit. This equation was:

y = -0.0005x3 - 0.0051x2 - 0.3885x + 29

Below is a picture of the preliminary testing that took place:

|

| Preliminary Flow Rate Experiment |

In-lab Activities:

The main activity in lab for this week included the adaptation of a user-friendly component to the Arduino board and ultimately to the final product. The introduction of a seven-segment display, and buttons would provide the user with the capabilities of adjusting the device to his/her options. Also, an Arduino accessory called the Positive RGB LCB Shield Kit provides character display and basic functions for a user. We talked about ways on how the either of the two displays can be implemented into the Arduino and its program to facilitate the devices outputs.

Below are two pictures that shows the two kinds of displays our group is considering:

|

| Seven-segment display |

|

| Arduino Display Shield |

This week brass barb fittings, tubing, hose clamps, and Teflon tape

were purchased. Upon further inspection,

the brass fittings were the wrong part and must be returned.

|

| Brass-barred fitting |

The new parts were purchased on the internet because they

were not available for in-store pickup. This

should not impede on construction time because this portion is basic

assembly. A discussion was also held

regarding the transport of the water from the jug to the valve. The design will use the tubing, however,

since the nozzle from the jug is tapered, the tubing cannot simply be clamped

on. One of the most suitable options so

far is to tap the nozzle so it can fit another brass fitting.

Next week in class we will begin putting together all of the subsystems and begin experimentation for the entire system's functionality.

Week 4

In-lab Activities:

The activities in lab for this week were based on the design of the two subsystems, the Arduino valve unit, and the plant watering frame. We came to the conclusion that developing a simple Arduino valve unit was best. The entire unit would be put together in a way that is both adherable to the base of the water tank, and easy to take apart in case of future programming. Our group also believed that the plant watering frame should be made from rubber hosing to provide the user with flexible adaptations.

Below is a picture of an Arduino board and a solder board placed together for appealing and flexible purposes:

|

| Arduino-solder board unit |

Outside-lab

The main activity outside of lab for this week involved the production of a valve unit for learning purposes. The group developed a prototype version of the solenoid valve. The solenoid valve unit prototype is made from a solenoid, two metal pipes, hose clamps, and rubber hosing. Water was able to be transported from a water source through the valve and out the other end.

Below is a picture of our prototype:

|

| Solenoid valve prototype |

The coding for the Arduino program was basically completed. Learning how to put together the valve's power source and connecting it to the computer program was this week's next step. The addition of the transistor was also taken into consideration. We learned about the different ways an Arudino unit can handle the amount of voltage a device can be given based on resistors. The implementation of the transistor will be useful in accomplishing the entire Arduino valve unit.

The following link provides information on how to properly run voltage to a system using an Arduino board and a power source:

Below is a model of a simple Arudino board unit comprised of a transistor and a power source:

|

| Model of an Arduino board with a transistor |

http://quarkstream.wordpress.com/2012/05/31/arduino-12-transistors/

In-lab Activities:

The activities in lab for this week included a brief with our technical advisers. We discussed power source for the Arduino. An additional deliverable was discussed: the wiring diagram of the Arduino component used in the device. Our group needs to do research on relays and transistors. A new concern is to find a way to safely power the device with an appropriate adapter and any relays necessary.

We made an adjustment to one of our constraints. We ordered our water tank. It is the Tablecraft 3-Gallon Beverage Dispenser. We also have to modify the nozzle of the water tank below. The final design needs to have a direct connection to the solenoid valve independent of the original spout.

Below is a picture of our water tank:

|

| Tablecraft 3-Gallon Beverage Dispenser |

Outside-lab activities:

This week, our group focused on the development of the Arduino board component of the project. The first component that had to be address was the transistor. A transistor would act as an on/off switch for the voltage passing through.

Below is a picture of the initial transistor that we acquired:

|

| Initial transistor acquired |

Below is a picture of a simple solder board that can be used for this subsytem:

|

| Simple Solder Board |

Week 2

In-lab Activities:

The activities in lab for this week included a revision process with our technical advisor. We discussed ways in how to improve the overall design and construction of the Automatic plant feeder. The group, alongside the technical advisor, gathered or loaned class-provided materials that included the following:

Week 1

In-lab Activities:

The activities for this week included the research of an appropriate project. The decided project was an automatic plant feeder that takes care of a plant's watering needs. The group made a preliminary sketch of this project, and decided on the simplest plant watering system. A discussion on the needed materials was also made. The materials that the group decided on were:

The sketch shows the different components that would have to go into building such a device. The components are labeled according to the list of materials listed above.

In-lab Activities:

The activities in lab for this week included a revision process with our technical advisor. We discussed ways in how to improve the overall design and construction of the Automatic plant feeder. The group, alongside the technical advisor, gathered or loaned class-provided materials that included the following:

- An Arduino UNO board

- A breadboard

- LED lights and resistors

- Wires

Below is a picture of the Arduino board unit the group will be using:

|

| A basic Arduino board setup |

A discussion on how to better develop a motor unit for rotational purposes also took place.

Outside-lab Activities:

The group has decided on a different approach to the intended device. The use of a solenoid valve will substitute the Arduino motor unit. An electrical current can be injected into the solenoid valve and water will flow through. The solenoid valve is an electric valve that can be wired to an Arduino board and essentially programmed. The solenoid valve is primarily composed of two components:Outside-lab Activities:

- A magnetic valve

- A solenoid that can lift the magnetic valve when powered

Below is a picture of an Arduino compatible solenoid valve:

|

| An Arduino compatible solenoid valve |

http://www.amazon.com/Electric-Solenoid-12-VDC-Normally-Closed/dp/B007N0GRIE/ref=sr_1_7/183-9668859-5183844?ie=UTF8&qid=1397525422&sr=8-7&keywords=arduino+solenoid

David researched five links on the basic of Arduino programming. The group will have to learn the basics of programming an Arduino unit. Below are five Arduino tutorial links:

- https://www.youtube.com/watch?v=fCxzA9_kg6s

- https://www.youtube.com/watch?v=_LCCGFSMOr4

- https://www.youtube.com/watch?v=abWCy_aOSwY

- https://www.youtube.com/watch?v=js4TK0U848I

- https://www.youtube.com/watch?v=5bHPKU4ybHY (This might be the most important)

After doing further research on the intended automatic plant feeder. The group came up with a secondary sketch, and most likely our final deliverable. The sketch illustrates the five main materials (or components) that will be incorporated into the device.

Below is a sketch of the current intended project:

Week 1

In-lab Activities:

The activities for this week included the research of an appropriate project. The decided project was an automatic plant feeder that takes care of a plant's watering needs. The group made a preliminary sketch of this project, and decided on the simplest plant watering system. A discussion on the needed materials was also made. The materials that the group decided on were:

- A table (placement of the water source)

- A Coleman Dispenser (a water source)

- A system of pipes (transportation of the water)

- Valve (flow of water)

- Motor (operates the valve)

- An Arduino board (program of the motor)

The group also delegated parts to compose for the design proposal.

Below is a sketch of the current intended project:

|

| Sketch of the current intended project |

Outside-lab activities:

Each person in the group composed a part of the design proposal. The finished design proposal was sent to every member. Outside of the classroom environment, the team began thinking of ways on how to develop a prototype that requires minimal effort to control the amount of water that travels from that tank (the water source) to the plant's roots. The group looked into previous patented self-watering systems. An intriguing water system was discovered. It explained the purpose of the self-watering system. The system is to read the moisture content of a given plant and have a mechanism understand when the plant needed water. The correlation between this patented watering system and our automatic watering system is that we want to control the amount of time our device delivers a preset amount of water to a given plant.

Below is a picture of the researched self watering system:

Research on the necessary materials we would need also began. The device would have to be composed of two subsystems:

Below is a picture of the researched self watering system:

|

| Researched self-watering system |

https://www.google.com/patents/US8584397?dq=automatic+plant+watering+system&hl=en&sa=X&ei=fllNU6a2H8TB0QGcmYCADg&ved=0CDUQ6AEwAA

Research on the necessary materials we would need also began. The device would have to be composed of two subsystems:

- A watering frame unit that includes the valve and a system of plastic pipes

- An Arduino motor unit that would control and operate the valve

The two subsystems would have smaller subsystems that would need to work cohesively to produce the intended product. A visual of our intended product was also researched. The Claber 8053 Oasis 4-Programs/20 Plants Garden Automatic Drip Watering System is an automated watering system that waters up to 20 plants.

Below is a picture a finished self watering system:

|

| Claber 8053 Oasis 4-Programs/20 Plants Garden Automatic Drip Watering System |

http://www.amazon.com/Claber-8053-4-Programs-Automatic-Watering/dp/B000U5YFR4

The use of plastic hosing seems to be an idea that can be implemented in our device. The group will start looking into the programming of the Arduino board to control the motor and ultimately the valve.